Will 3D printed saddles represent the future of bicycle saddles?

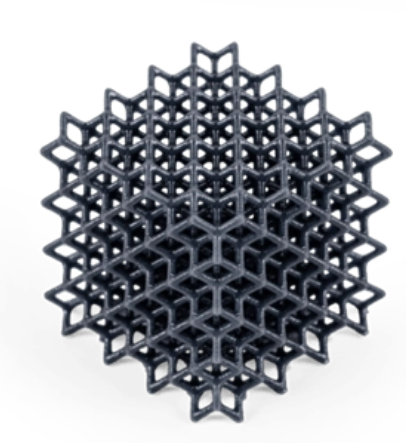

Design of 3D printed saddle – lattice structure

Very special. The lattice structure is not just a matter of aesthetics but also means that a precise seating feel can be achieved. We algorithmically designed a partitioned lattice structure to achieve differentiated support areas.

It can also be clearly seen in the picture: when the crystal lattice is thinner and the rod diameter is thinner, what we feel is a softer area. When the crystal lattice is denser and thicker, it will provide more support. At the same time, the hollow lattice structure also allows the seat cushion to have a natural breathable function, which can greatly alleviate the problem of sweating during riding.

Will 3D printed saddles represent the future of bicycle saddles?

3D printed saddles have huge potential and have already carved out a significant space in this market. We can make full use of the 3D saddle's differentiated support area and breathable performance advantages for mass production.

In addition, the design of 3D printed bicycle saddles can be personalized for the comfort, health and performance of athletes. Mass customization is where additive manufacturing comes into play.